- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

- Tag List

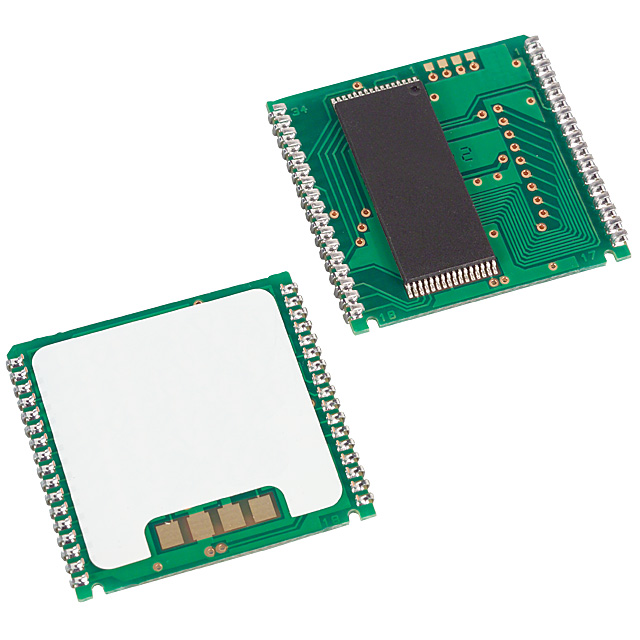

- Power Supply Module: A Comprehensive Guide from Fundamental Architecture to Cutting-Edge Applications

Power Supply Module: A Comprehensive Guide from Fundamental Architecture to Cutting-Edge Applications

1. Definition and Core Value of Power Supply Modules https://www.sic-components.com/power-supplies-externalinternal-off-board/ac-dc-configurable-power-supply-modules/

A Power Supply Module is a standardized power subsystem that integrates power conversion components—such as controllers, power devices, and magnetic elements—into a single package. Unlike traditional discrete designs, it transforms complex power conversion functions into "plug-and-play" solutions through pre-integration and optimized testing. Its core values include:

Design Efficiency: Reduces development cycles from hundreds of hours (discrete) to weeks.

Reliability Enhancement: Failure rates are 60% lower than discrete solutions via standardized manufacturing and pre-verification.

Space Optimization: Achieves power densities up to 100W/cm³ for high-density systems.

2. Technical Architecture and Operational Principles

2.1 Core Components and Integration Technologies

Key Components:

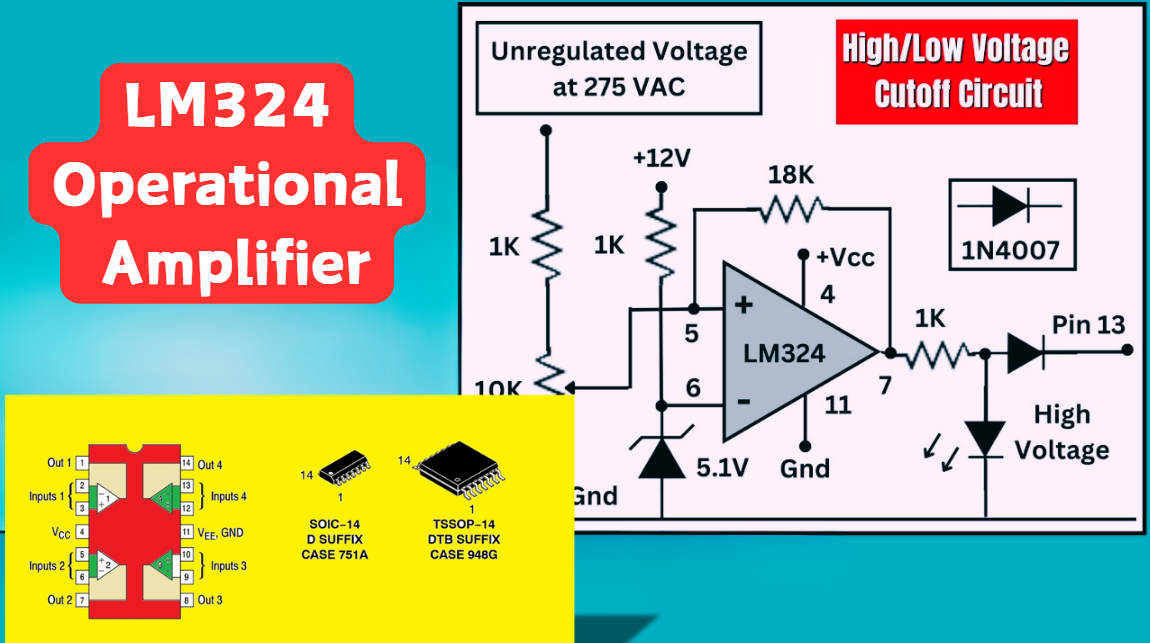

Control Chips: Integrate PWM controllers (e.g., TI's LM5146) or digital power management units (PMUs).

Power Stage: Uses synchronous MOSFETs (Si) or wide-bandgap devices (GaN/SiC) with \(R_{DS(on)}\) as low as 10mΩ.

Magnetic Components: Planar inductors/transformers with ferrite/nanocrystalline cores, supporting saturation currents up to 150A.

Auxiliary Circuits: Include compensation networks, protection circuits (overcurrent/voltage/temperature), and communication interfaces.

Integration Processes:

Multi-Layer Substrate Technology: AlN ceramic substrates enable low thermal resistance (\(R_{thJA} < 5°C/W\)) and high dielectric strength.

3D Stacked Packaging: Vertical stacking of controllers, power devices, and inductors reduces parasitic inductance to <5nH.

Potting Technology: Thermal silicone or epoxy resin enhances heat dissipation and moisture resistance (IP65 rating).

2.2 Typical Topologies and Working Mechanisms

Take the synchronous buck module (e.g., MPS MP8694) as an example:

Input Stage: X7R ceramic capacitors (10μF/25V) filter high-frequency noise.

Conversion Stage:

High-side switch (80V rating) conducts at 1.2MHz to store energy in the inductor.

Low-side switch (40V rating) conducts during dead time to maintain output current continuity.

Output Stage: Low-ESR electrolytic capacitors (e.g., Panasonic EEU-FM series) stabilize voltage with ripple controlled within ±1%.

Efficiency: In 48V→12V/30A scenarios, SiC modules achieve 97% efficiency—5% higher than traditional Si solutions.

3. Classification and Technical Characteristics

3.1 Classification by Conversion Type

Type Typical Topology Input Voltage Range Output Power Core Application Scenarios

Non-Isolated DC/DC Buck/Boost/Buck-Boost 5V~1000V 1W~500W Server POL, industrial control

Isolated DC/DC Flyback/LLC/Phase-Shifted Full Bridge 24V~1500V 50W~2kW Railway traction, medical equipment

AC/DC Module Totem Pole PFC+LLC 85VAC~380VAC 100W~10kW Communication power, new energy chargers

LED Driver Module Buck/PWM Dimming 12V~100V 10W~200W Landscape lighting, automotive headlights

3.2 Classification by Core Technology

Traditional Silicon Modules: Mature, cost-effective, suitable for switching frequencies ≤100kHz.

Wide-Bandgap (WBG) Modules:

GaN modules (e.g., Navitas NV6127): Switching speed >1MHz, 30% smaller size.

SiC modules (e.g., Wolfspeed CAB1200): Temperature tolerance up to 175°C for high-voltage scenarios.

Digital Power Modules: Support I2C/SPI communication (e.g., ADI LTM4678) for real-time voltage/current/temperature monitoring.

4. Application Scenarios and Industry Solutions

4.1 Data Centers and Cloud Computing

High-Voltage DC (HVDC) Conversion:

48V→12V distributed power: Vicor VIA series modules (VI-269) support 1500V isolation with 98% efficiency.

High-Density POL Power Supply:

CPU/GPU power: TI's LMZM23601 (6A/2mm×2mm) supplies 1.1V/6A for DDR5 memory.

Computing clusters: 16-phase modules (e.g., MPS MP8694) support 120A total current for AI chips (e.g., NVIDIA A100).

4.2 New Energy and Electric Vehicles

On-Board Power Systems:

OBC (On-Board Charger): Infineon EiceDRIVER modules enable 3.3kW~22kW charging with >95% efficiency.

48V mild hybrid systems: TDK-Lambda Z+ series modules (200W) power starters/generators.

Photovoltaics and Energy Storage:

String inverters: SMA Sunny Boy modules support 1500V DC input with 1.5W/cm³ power density.

4.3 Medical and Aerospace Applications

Medical Equipment:

MRI systems: ADI LTM4678 (15A) provides ±0.5% precision power for gradient magnetic field stability.

Portable devices: Linear Technology LTM8064 (3A/3mm×3mm) supports 9V~36V input for handheld ultrasound devices.

Aerospace:

Satellite power: MIL-PRF-38534 Class H modules (e.g., CDE 947D series) withstand -55°C~+125°C temperature cycles.

5. Design Selection and Implementation Considerations

5.1 Key Parameter Evaluation

Electrical Parameters:

Input voltage range (e.g., 2:1 wide input or 4:1 ultra-wide input).

Load regulation (≤±0.5%) and line regulation (≤±0.1%).

Dynamic response (e.g., overshoot <100mV for 10A/μs load steps).

Environmental Parameters:

Operating temperature range (industrial: -40°C~+85°C; automotive: -40°C~+125°C).

Altitude derating (3% per 1000m above 1000m).

5.2 Layout and Thermal Design

Input Filtering: Parallel 10μF X7R capacitors with 0.1μF ceramic capacitors within 5mm of module inputs.

Thermal Management:

Thermal vias (0.3mm diameter, ≥10 pieces) conduct heat to inner copper layers.

High-power modules (>50W) require heat sinks with thermal resistance targets <10°C/W.

EMI Control:

Series beads (100Ω/100MHz) at the output suppress high-frequency noise.

Ground planes under modules reduce common-mode interference.

6. Industry Competition and Leading Products

6.1 International Manufacturers and Representative Products

Texas Instruments (TI):

Integrated inductor module LMZM23601 (6A/2mm×2mm) for server POL.

Digital power module LM5146 (40V/5A) supporting PMBus communication.

Analog Devices (ADI):

μModule® series LTM4678 (15A) with built-in compensation networks for precision medical equipment.

LTC7890 (60V/10A) supporting bidirectional Buck-Boost for energy storage systems.

Renesas:

Mini Module series RAA210040 (4A/3mm×3mm) for 5G base stations.

Automotive-grade module RAA227001 (12A) compliant with AEC-Q100 Grade 1.

6.2 Innovations from Domestic Manufacturers

MeixinSheng (MTK): High-power density AC/DC modules (65W/2cm³) for GaN chargers.

XinPai Technology: Isolated DC/DC modules (1500V/200W) for photovoltaic inverters.

Invictus: Data center power modules (240V HVDC→12V/50A) with 97.5% efficiency.

7. Technological Trends and Cutting-Edge Innovations

7.1 Popularization of Wide-Bandgap Devices

GaN Technological Breakthroughs:

By 2025, 40% of 100W+ modules are expected to use GaN (Yole data), e.g., EPC's EPC2059 (100V/30A) modules.

Advantages: 70% lower switching losses, 50% smaller size, suitable for high-frequency fast charging (1MHz+).

SiC Module Evolution:

Automotive-grade SiC modules (e.g., Rohm SCT3080KE) support 1200V/800A for 800V EV platforms.

7.2 Intelligence and Integration

Digital Power Management:

AI predictive maintenance: Optimizes load distribution via machine learning (e.g., Monolithic Power's mCloud platform).

Real-time health monitoring: Integrates ADC and temperature sensors for early fault warning.

Heterogeneous Integration Technologies:

3D packaging: Intel EMIB technology stacks controllers, MOSFETs, and inductors, boosting power density to 200W/cm³.

System-in-Package (SiP): Integrates power modules with MCUs for IoT edge devices.

7.3 Green and Sustainable Design

Lead-Free and Environmentally Friendly Materials:

Uses Sn99.3Cu0.7 solder and halogen-free potting compounds (e.g., Dow Corning Sylgard 160).

Upgraded Energy Efficiency Standards:

Meets 80 PLUS Titanium (≥96% efficiency) and CQC high-efficiency certifications.

Innovative Thermal Management:

Phase Change Material (PCM) cooling reduces module temperature by 15°C in 40°C environments.

8. Case Study: 48V to 12V Vehicle Power Supply Module

8.1 Application Background

New energy vehicle 48V mild hybrid system requirements for starters and air conditioning compressors:

Input: 40V~56V (battery dynamic range).

Output: 12V/30A (ripple <50mV).

Efficiency: ≥95% (ISO 12405-2 standard).

8.2 Module Solution Selection

Infineon OptiMOS™ Module:

Topology: Synchronous Buck (integrated 100V/20mΩ MOSFET).

Control: TLE94712G controller supporting automatic PWM/PFM switching.

Magnetic Components: Planar inductor (4.7μH, saturation current 40A).

8.3 Performance Verification

Efficiency Curve: 92% at light load (10%) and 96.1% at full load for 48V→12V/30A.

Thermal Performance: Module surface temperature of 58°C at 25°C ambient (fanless).

Reliability: Passed AEC-Q100 Grade 1 testing (-40°C~+125°C, 1000 thermal cycles).

9. Future Outlook: Industrial Transformation of Power Modules

Power modules are evolving from "functional integration" to "system enablement," with core trends including:

Integration of Computing and Power: Collaborative design of AI chips and power modules for dynamic power optimization.

Metamaterial Applications: Topological insulators for core materials, enhancing inductor efficiency by 15%.

Energy Internet Adaptation: Bidirectional power modules support V2G (vehicle-grid interaction) and microgrid scheduling.

Reconfigurable Power: Software-Defined Power (SDP) technology enables single modules to support multiple voltage outputs.

For designers, choosing power modules is no longer just a technical decision but a strategic consideration of time-to-market and full lifecycle costs. With the explosion of 5G, AI, and new energy sectors, power modules will drive power electronics innovation with higher density, efficiency, and intelligence.

https://www.sic-components.com/power-supplies-externalinternal-off-board/ac-dc-configurable-power-supply-modules/

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)