- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Electronic Components Manufacturing Company

In the heart of the global electronics manufacturing ecosystem, SIC Electronic Components Manufacturing Company stands as a testament to precision, innovation, and technological excellence. Specializing in the design, development, and production of a wide array of electronic components, SIC has carved a niche for itself by delivering high-reliability solutions that power everything from consumer gadgets to advanced industrial systems. This article explores the company’s core strengths, product portfolio, technological edge, and its role in shaping the future of electronics.

1. Company Overview: A Legacy of Excellence

Founded with a vision to bridge the gap between cutting-edge research and practical applications, SIC was established in 2001 by a team of engineers and industry veterans. Headquartered in America, the company operates state-of-the-art manufacturing facilities in many key regions, leveraging automation, AI-driven quality control, and lean production methodologies to ensure scalability and consistency. Over the decades, SIC has evolved from a regional player to a global leader, serving clients in over 200 countries across industries such as automotive, aerospace, renewable energy, IoT, and consumer electronics.

Mission & Values:

Mission: To empower global innovation by providing electronic components that combine performance, reliability, and cost-effectiveness.

Values: Integrity in partnerships, commitment to sustainability, and a customer-centric approach to problem-solving.

2. Core Product Portfolio: Solutions for Every Electronics Need

SIC’s diverse product lineup caters to the full spectrum of electronic systems, with a focus on high-tech components that meet the demands of modern applications:

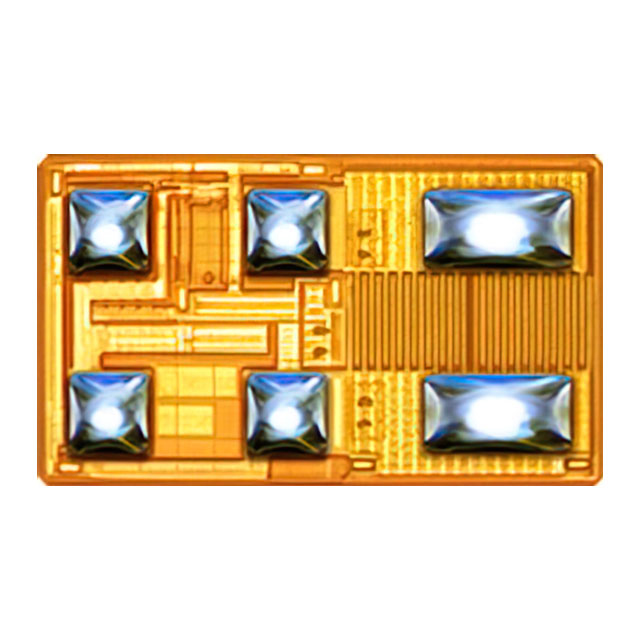

A. Semiconductor Products

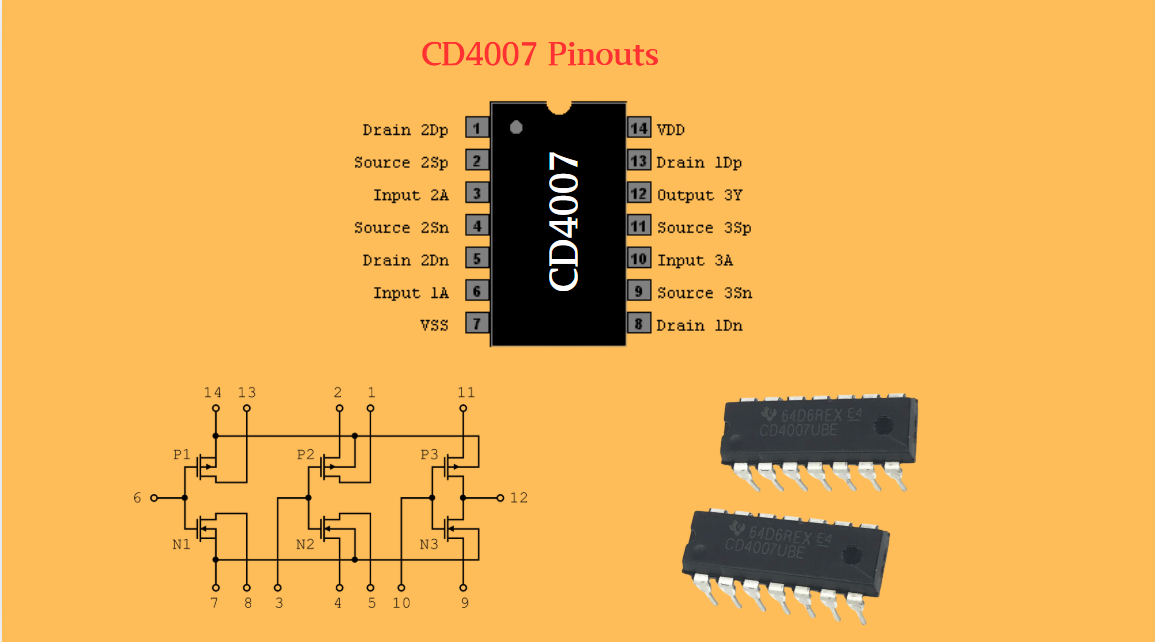

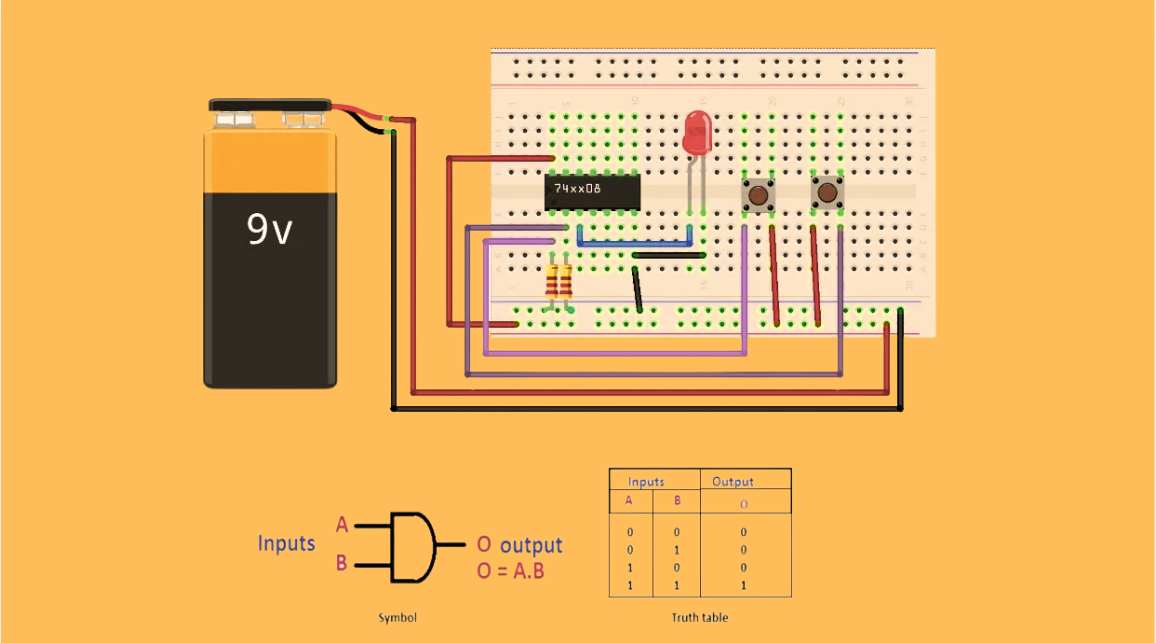

Integrated Circuits (ICs):

Microcontrollers (MCU) and microprocessors (MPU) for embedded systems, available in ARM, RISC-V, and proprietary architectures.

Power management ICs (PMICs) for energy-efficient devices, including DC-DC converters, battery chargers, and LED drivers.

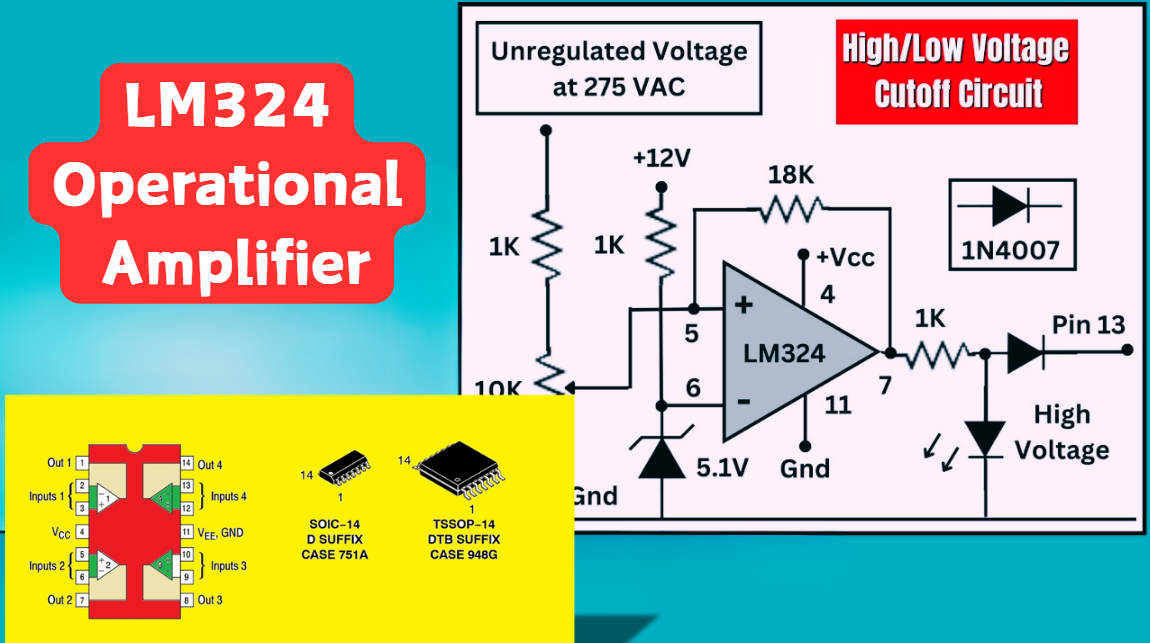

Analog ICs such as operational amplifiers, data converters (ADC/DAC), and voltage regulators for precision signal processing.

Discrete Semiconductors:

High-power MOSFETs, IGBTs, and SiC/GaN devices for electric vehicles (EVs), solar inverters, and industrial motor drives.

Diodes (Schottky, Zener, TVS) and thyristors for circuit protection and power rectification.

B. Passive Components

Capacitors: MLCCs (multi-layer ceramic), electrolytic, film, and tantalum capacitors, optimized for high frequency, high voltage, or high-temperature environments.

Resistors: Chip resistors, wire-wound resistors, and precision thin-film resistors with tolerances as low as ±0.01%.

Inductors & Chokes: Power inductors for DC-DC converters, RF inductors for wireless applications, and common-mode chokes for noise suppression.

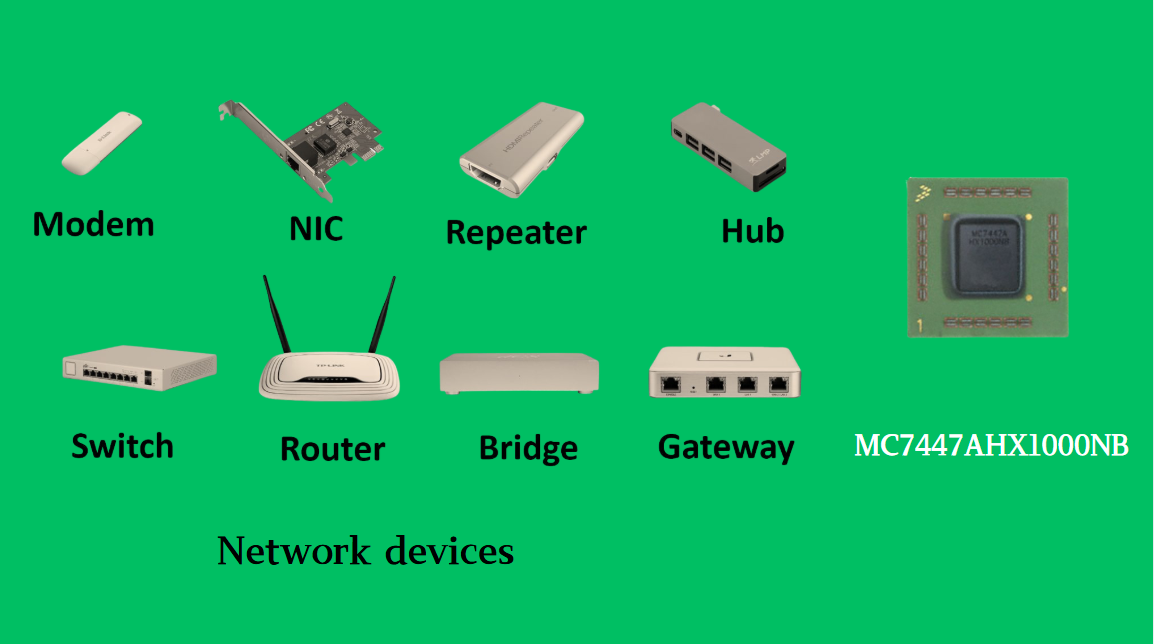

C. Sensors & Frequency Control

Sensors: Hall effect sensors, temperature sensors, and pressure sensors for industrial automation and smart devices.

Frequency Control: Crystals, oscillators (TCXO, OCXO), and resonators ensuring stable timing in communication systems and GPS modules.

D. Interconnect & Electromechanical Components

Connectors: High-reliability connectors for board-to-board, cable-to-board, and ruggedized applications (IP67/IP68 rated).

Cables & Assemblies: Custom cable harnesses, coaxial cables, and HDMI/USB connectors for data and power transmission.

Enclosures & Hardware: Die-cast aluminum enclosures, ESD-safe packaging, and fasteners compliant with RoHS/REACH standards.

E. Advanced Technologies

Silicon Carbide (SiC) & Gallium Nitride (GaN): Next-generation semiconductors for high-power, high-temperature applications, reducing energy loss by up to 50% compared to silicon.

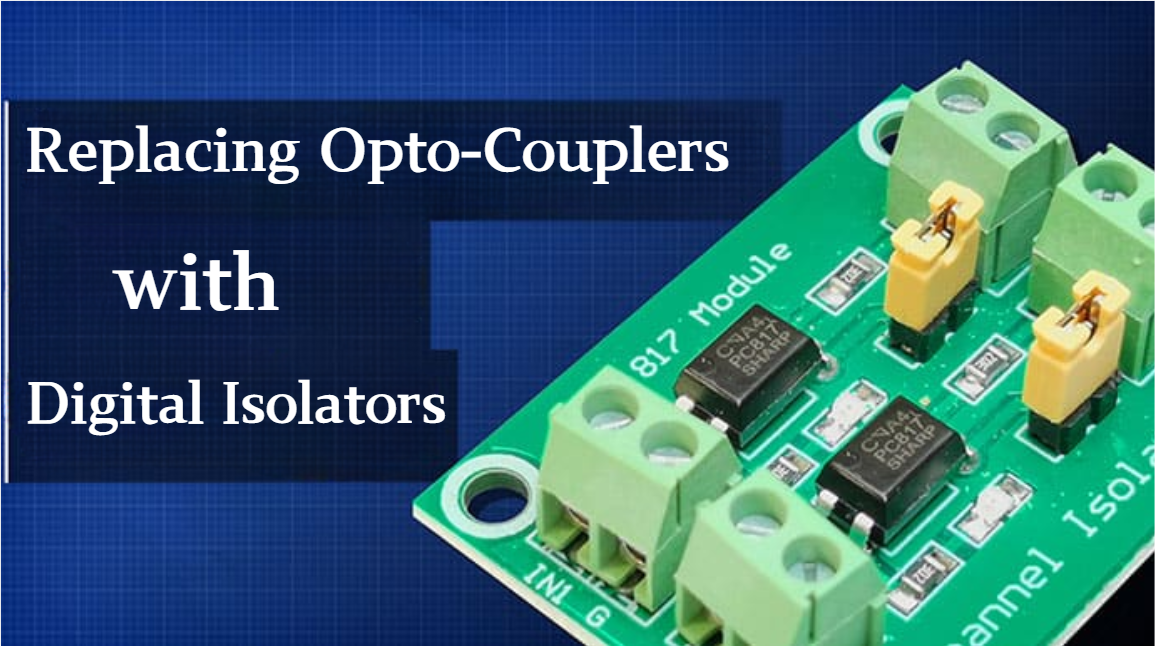

RFID & Wireless Solutions: Passive UHF RFID tags and NFC modules for inventory management and contactless systems.

3. Technological Edge: Innovation as a Core Driver

SIC’s competitive advantage lies in its relentless focus on R&D, with over 30% of annual revenue invested in innovation. The company operates a dedicated R&D center staffed by PhD-level engineers and collaborates with leading universities and research labs to develop cutting-edge solutions:

Material Science: Research into nanocomposites for capacitors and high-temperature dielectrics for harsh environments.

Design Tools: Proprietary simulation software (e.g., SPICE models for ICs, 3D electromagnetic field solvers for RF components) to accelerate customer design cycles.

Sustainability: Development of lead-free, halogen-free components and energy-efficient manufacturing processes, aligning with global green initiatives.

4. Manufacturing Excellence & Quality Assurance

SIC’s manufacturing facilities are certified to ISO 9001, IATF 16949 (for automotive), and ISO 13485 (for medical devices), ensuring compliance with the strictest industry standards. Key manufacturing capabilities include:

Automation: Robotic pick-and-place systems for SMD components, with a placement accuracy of ±50 microns.

Testing Labs: Equipped with ATE (automated test equipment) for IC validation, thermal chambers (-55°C to +150°C), and EMC/EMI testing facilities.

Traceability: Blockchain-based systems for end-to-end component tracking, from raw material sourcing to final shipment.

5. Market Applications: Powering Diverse Industries

A. Automotive Electronics

EV battery management systems (BMS) using SiC MOSFETs for efficient energy conversion.

Advanced driver-assistance systems (ADAS) enabled by high-temperature sensors and rugged connectors.

B. Industrial Automation

PLCs (programmable logic controllers) and motor drives powered by SIC’s IGBT modules, ensuring reliability in 24/7 operations.

IoT sensors for predictive maintenance in smart factories.

C. Renewable Energy

Inverters for solar/wind systems using GaN devices to maximize energy yield and minimize downtime.

Energy storage solutions with precision PMICs for battery balancing.

D. Consumer Electronics

Miniaturized components for wearables (e.g., low-power MCUs, tiny MLCCs) and smartphones (RF filters, fast-charging ICs).

6. Global Supply Chain & Customer Collaboration

SIC’s global presence is supported by a robust supply chain network, with regional offices in North America, Europe, and APAC. The company emphasizes collaborative partnerships:

Design-In Support: Dedicated FAE (field application engineer) teams assist customers with component selection, prototyping, and troubleshooting.

Custom Solutions: Tailored components for unique requirements, such as military-grade temperature tolerance or aerospace-specific packaging.

Logistics: Agile inventory management using AI algorithms to predict demand and mitigate supply chain disruptions, with lead times as low as 2 days for standard products.

7. Challenges & Future Vision

While SIC faces challenges such as global chip shortages and rising material costs, the company remains resilient through:

Localization Strategies: Expanding manufacturing in regions with high demand (e.g., Southeast Asia for consumer electronics, Europe for automotive).

Digital Transformation: Implementing AI in quality control and predictive maintenance to enhance yield and reduce waste.

Future Goals:

Become a top 5 global supplier in SiC/GaN components by 2030.

Achieve 100% renewable energy usage in manufacturing by 2028.

Launch a dedicated R&D lab for quantum electronics by 2026.

Conclusion: Shaping the Future of Electronics

SIC Electronic Components Manufacturing Company is more than a component supplier; it is a catalyst for technological progress. By combining engineering expertise, manufacturing excellence, and a customer-first mindset, SIC empowers industries to innovate fearlessly, knowing their components are built to withstand the rigors of tomorrow’s applications. As the electronics landscape evolves toward smarter, greener, and more interconnected systems, SIC stands ready to lead the charge, proving that quality and innovation are not just standards—they are the foundation of enduring success.

For more information, visit [SIC Company Website] or contact their global sales team to explore how their components can elevate your next project.

https://www.sic-components.com/category-all

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)