- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

What is a resistance temperature detector RTD Sensor? : A Comprehensive Guide

A Resistance Temperature Detector(https://www.sic-components.com/rtd-resistance-temperature-detector), commonly known as an RTD sensor, is a highly precise temperature - sensing device that operates based on the principle of the change in electrical resistance of a material with temperature variations. At its core, an RTD consists of a resistive element, typically made of pure metals like platinum, nickel, or copper. Among these, platinum is the most widely used due to its exceptional stability, linear resistance - temperature relationship, wide temperature range, and chemical inertness.

The fundamental characteristic of an RTD is that its resistance increases linearly as the temperature rises. This predictable relationship allows for accurate temperature measurement by simply measuring the resistance of the element and converting it into a corresponding temperature value. RTDs are renowned for their high accuracy, repeatability, and long - term stability, making them a preferred choice in numerous applications where precise temperature monitoring is crucial.

The developments of RTD Sensor (https://www.sic-components.com/rtd-resistance-temperature-detector)

The development of RTD sensors has a rich history that dates back to the understanding of the relationship between temperature and electrical resistance of metals. Early experiments in the 19th century laid the foundation for the concept of using metal resistance changes for temperature measurement.

In the mid - 20th century, with the advancement of materials science and manufacturing techniques, RTDs started to become more practical and widely used. The standardization of platinum as the primary material for RTD elements was a significant milestone. Platinum offered excellent stability over a wide temperature range, which was essential for industrial applications.

Advancements in manufacturing processes, such as wire - winding and thin - film deposition, further improved the performance and cost - effectiveness of RTDs. Wire - wound RTDs, with their fine platinum wire coils, provided high accuracy but were relatively expensive to produce. The introduction of thin - film RTDs, which involved depositing a thin layer of platinum on a ceramic substrate, offered a more cost - effective alternative while maintaining good accuracy and reliability.

In recent years, with the growth of the Internet of Things (IoT) and smart sensor technologies, RTDs have been integrated with digital interfaces and wireless communication capabilities, enabling real - time temperature monitoring and remote control in various applications.

Elements of RTD Sensor (https://www.sic-components.com/rtd-resistance-temperature-detector)

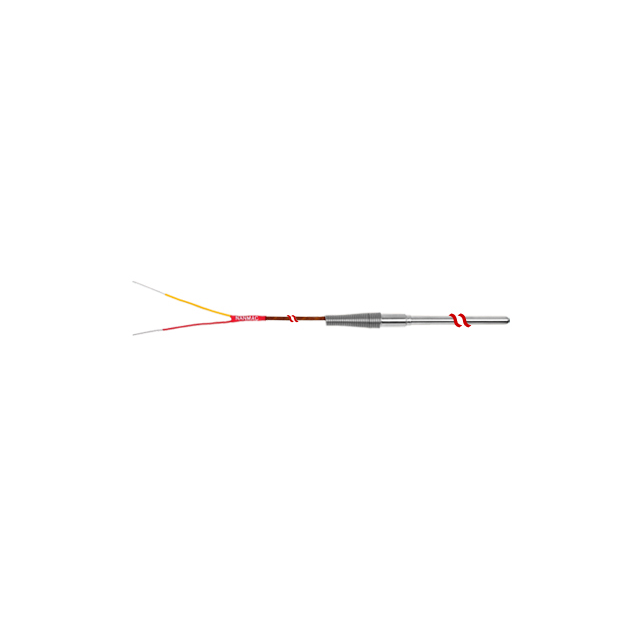

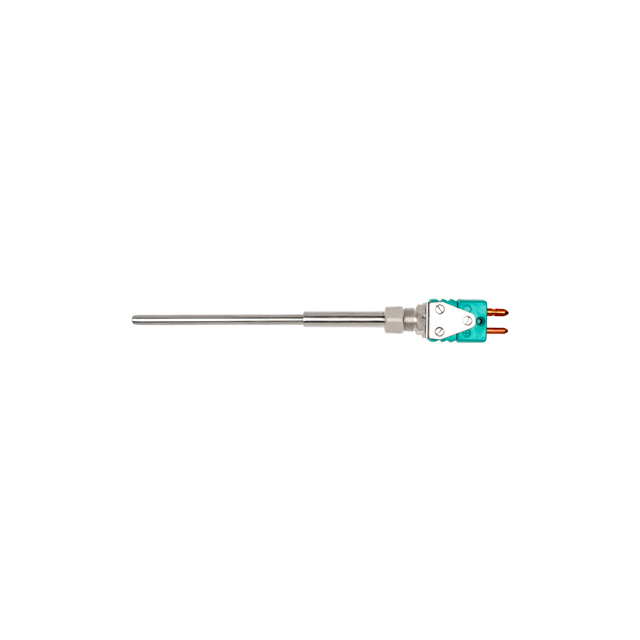

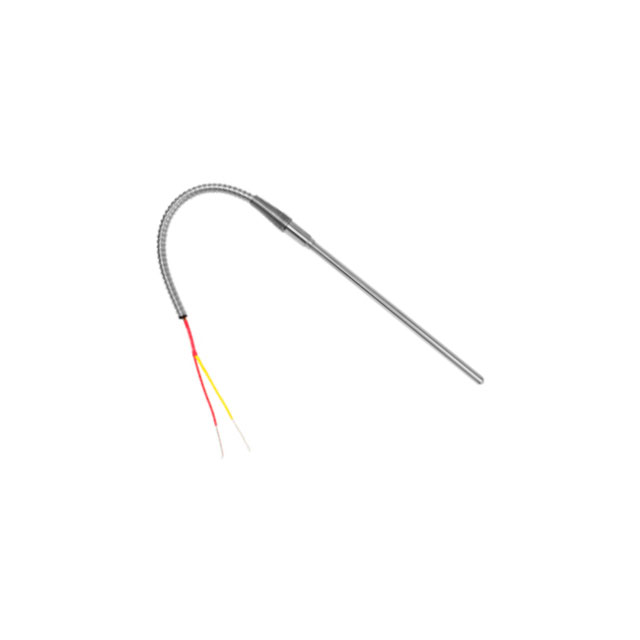

Resistance Element: This is the heart of the RTD sensor. As mentioned, it is usually made of platinum, but nickel and copper can also be used in some cases. The resistance element is designed to have a specific resistance value at a reference temperature (commonly 0°C), such as 100 ohms for a PT100 RTD. The choice of material and its construction determine the sensor's accuracy, temperature range, and stability.

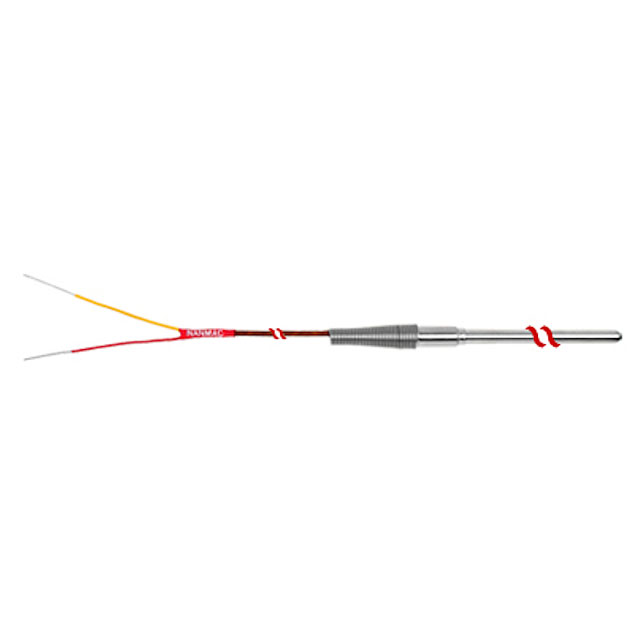

Insulated Wires: These wires are used to connect the resistance element to the measurement circuit. They are insulated to prevent electrical short - circuits and interference. In some RTDs, especially those used in industrial applications, additional wires (three or four - wire configurations) are used to compensate for lead wire resistance and improve measurement accuracy.

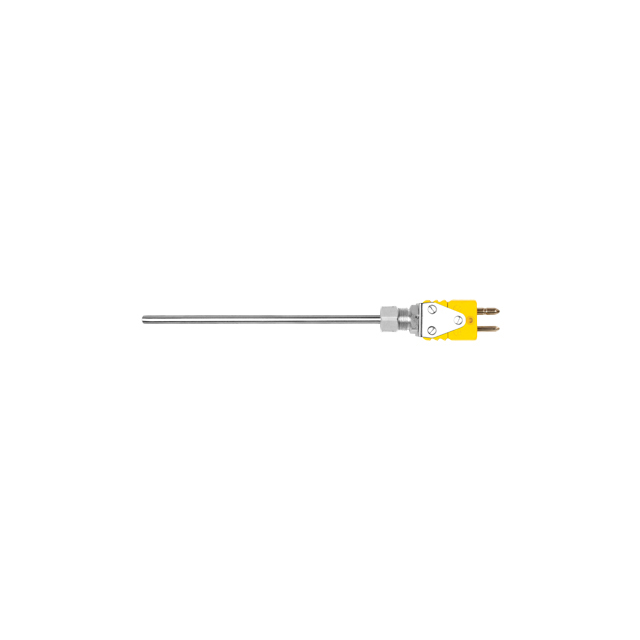

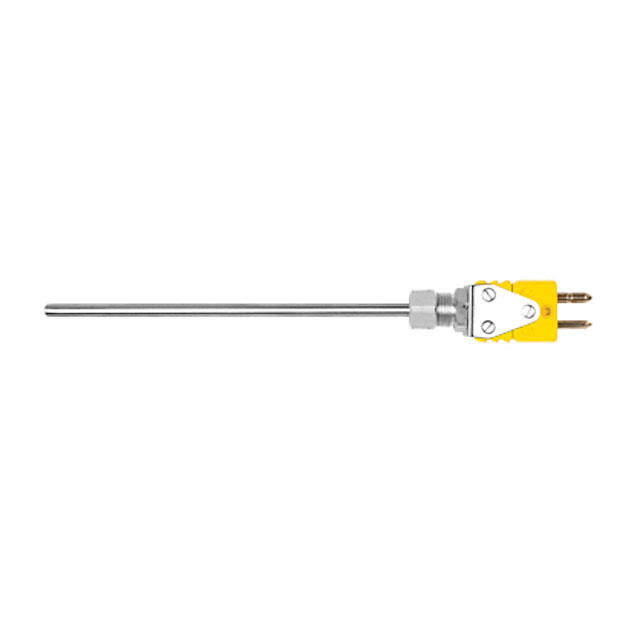

Protective Probe or Housing: The resistance element and wires are housed in a protective probe or housing. This protects the internal components from physical damage, moisture, chemicals, and other environmental factors. The housing can be made of materials such as stainless steel, ceramic, or glass, depending on the application requirements. For example, in high - temperature or corrosive environments, a more robust and chemically resistant housing is required.

How Does a RTD Sensor Work? (https://www.sic-components.com/rtd-resistance-temperature-detector)

The working principle of an RTD sensor is based on the positive temperature coefficient of resistance (PTCR) of the metal used in the resistance element. When an electrical current is passed through the RTD, the resistance element acts as a resistor. As the temperature of the resistance element increases, the kinetic energy of the metal atoms within it also increases. This increased atomic motion disrupts the flow of electrons, resulting in an increase in electrical resistance.

The resistance of the RTD at a given temperature can be calculated using the following formula (for a simple linear approximation):

RT=R0(1+α(T−T0 )), where RT is the resistance at temperature T, R0 is the resistance at the reference temperature T0, α is the temperature coefficient of resistance, which is a characteristic property of the metal used in the RTD.

To measure the temperature, a known current is passed through the RTD, and the resulting voltage drop across it is measured. Using Ohm's law (V=IR), the resistance of the RTD can be calculated. Once the resistance is known, the temperature can be determined by referring to the calibration curve of the specific RTD, which maps the resistance - temperature relationship.

Types of RTD Sensor (https://www.sic-components.com/rtd-resistance-temperature-detector)

Wire - wound RTDs: These RTDs have a sensing element that consists of a small coil of ultra - thin platinum wire. The wire is carefully wound around a glass or ceramic core. The core provides mechanical support and insulation to the wire. Wire - wound RTDs are known for their high accuracy and stability. They can be used to measure a wide range of temperatures, and those with glass cores are suitable for immersion in many liquids, while ceramic - cored wire - wound RTDs can accurately measure extremely high temperatures. However, they are more expensive to produce due to the labor - intensive wire - winding process and are more sensitive to vibrations.

Thin - film RTDs: In thin - film RTDs, a thin layer of metal (usually platinum) is deposited on a ceramic substrate. The metal film is then laser - cut or etched into an electrical circuit pattern to achieve the desired resistance value. After that, lead wires are attached, and a protective glass coating is applied. Thin - film RTDs are more cost - effective to produce compared to wire - wound RTDs and are more resistant to vibrations. They are reliable and are commonly used in applications where cost - effectiveness and moderate accuracy are required, such as in consumer electronics and some industrial monitoring systems.

Functions of RTD Sensor (https://www.sic-components.com/rtd-resistance-temperature-detector)

Temperature Measurement: The primary function of an RTD sensor is to accurately measure the temperature of its surroundings. Whether it is monitoring the temperature of a fluid in a pipeline, the internal temperature of an electronic device, or the ambient temperature in a room, RTDs can provide precise temperature readings.

Process Control: In industrial processes, RTD sensors play a crucial role in process control. They are used to monitor and regulate the temperature of reactors, furnaces, heat exchangers, and other equipment. By providing real - time temperature data, RTDs enable control systems to adjust heating or cooling elements, ensuring that the process operates within the desired temperature range for optimal product quality and efficiency.

Quality Assurance: In manufacturing and production industries, RTDs are used to ensure the quality of products. For example, in the food processing industry, they monitor the cooking and cooling temperatures of food products to ensure food safety and quality. In the semiconductor manufacturing process, precise temperature control is essential for the fabrication of high - quality chips, and RTDs help maintain the required temperature conditions.

Environmental Monitoring: RTD sensors are also used in environmental monitoring applications. They can measure the temperature of air, water, and soil in environmental research, weather stations, and pollution monitoring systems. This data is valuable for understanding climate change, ecosystem health, and environmental trends.

Applications of RTD Sensor (https://www.sic-components.com/rtd-resistance-temperature-detector)

Industrial Automation: In industrial plants, RTDs are used in a wide variety of applications. They are installed in chemical plants to monitor the temperature of chemical reactions, in power plants to measure the temperature of steam, turbines, and generators, and in manufacturing facilities to control the temperature of injection molding machines, ovens, and furnaces.

Automotive Industry: RTD sensors are used in vehicles to measure the temperature of engine coolant, engine oil, transmission fluid, and intake air. This information is used by the vehicle's onboard computer to optimize engine performance, improve fuel efficiency, and ensure the longevity of engine components.

Food and Beverage Industry: In food processing, RTDs are used to monitor the cooking, baking, pasteurization, and refrigeration temperatures of food products. They help ensure food safety by preventing the growth of harmful bacteria and maintaining the quality and taste of the food. In the beverage industry, they are used to control the fermentation and bottling temperatures.

Medical and Pharmaceutical Industry: RTDs are used in medical devices such as incubators, patient monitoring systems, and pharmaceutical manufacturing equipment. They are crucial for maintaining the correct temperature for the growth and preservation of biological samples, the storage of drugs, and the comfort and safety of patients.

HVAC Systems: In heating, ventilation, and air - conditioning (HVAC) systems, RTDs are used to measure the temperature of air in buildings. This information is used to control the heating and cooling units, ensuring a comfortable indoor environment while optimizing energy consumption.

RTD vs. Thermocouples (https://www.sic-components.com/rtd-resistance-temperature-detector)

Temperature Range: Thermocouples generally have a wider temperature range compared to RTDs. Thermocouples can measure temperatures from - 200°C to over 2000°C, making them suitable for high - temperature applications such as in steel mills, kilns, and gas turbine exhausts. RTDs, on the other hand, typically operate within a range of - 200°C to 600°C, although some specialized RTDs can extend this range.

Accuracy and Stability: RTDs offer higher accuracy and better long - term stability within their operating range. Their resistance - temperature relationship is highly linear, allowing for more precise temperature measurements. Thermocouples, while still accurate, have a non - linear relationship between temperature and the generated voltage, which may require more complex calibration and compensation techniques. Additionally, thermocouples can be affected by factors such as oxidation, contamination, and mechanical stress, which can lead to changes in their output over time.

Response Time: Thermocouples usually have a faster response time compared to RTDs. This is because they do not rely on the thermal mass of a resistive element like RTDs. Thermocouples can quickly respond to rapid temperature changes, making them suitable for applications where real - time temperature monitoring of dynamic processes is required. RTDs, due to the thermal inertia of their resistance elements, may have a slower response, especially in situations with fast - changing temperatures.

Cost: Thermocouples are generally more cost - effective than RTDs. The materials and manufacturing processes for thermocouples are relatively simpler, which reduces their production cost. RTDs, especially those made of platinum, are more expensive due to the cost of the precious metal and the precision manufacturing techniques required.

Self - heating: RTDs can experience self - heating, especially when a relatively large current is passed through them for resistance measurement. This self - heating can cause an error in the temperature measurement if not properly accounted for. Thermocouples, on the other hand, do not have a significant self - heating effect as they generate a voltage based on the thermoelectric effect rather than passing a current through a resistive element.

Resistance Temperature Detector Technical Information (https://www.sic-components.com/rtd-resistance-temperature-detector)

Standard Tolerances: RTDs are manufactured to several tolerance standards. One of the most common is the DIN (Deutsches Institut für Normung) standard. DIN RTDs are classified into different tolerance classes, such as Class A, Class B, and Class C.

DIN Class A: Has a tolerance of ±(0.15 + 0.002|T|°C), where T is the measured temperature. This class offers the highest accuracy and is suitable for applications requiring precise temperature measurement.

DIN Class B: Has a tolerance of ±(0.3 + 0.005|T|°C), which is less accurate than Class A but still suitable for many industrial applications.

DIN Class C: Has a tolerance of ±(1.2 + 0.005|T|°C) and is used in applications where lower accuracy requirements are acceptable.

Element Types: The most common type of RTD element is the 100 Ohm Platinum RTD with a temperature coefficient of 0.00385 Ohm/Ohm/°C. However, other element types with different resistance values and temperature coefficients are also available. When selecting an RTD element, it is important to consider the compatibility with the measurement instrument, as different instruments may be designed to work with specific element types.

Accuracy: The accuracy of an RTD is determined by a combination of the base resistance tolerance (the tolerance of the resistance at the calibration temperature, usually 0°C) and the temperature coefficient of resistance tolerance (the tolerance in the slope of the resistance - temperature relationship). Higher - quality RTDs with tighter tolerances will provide more accurate temperature measurements. However, it should be noted that the accuracy of an RTD may decrease as the temperature deviates from the calibration temperature.

RTD Sensor Frequently Asked Questions (https://www.sic-components.com/rtd-resistance-temperature-detector)

Q: Why is platinum the preferred material for RTDs?

A: Platinum is preferred because it offers excellent long - term stability, a highly linear relationship between temperature and resistance, a wide operating temperature range, and chemical inertness. These properties ensure accurate and reliable temperature measurement over extended periods and in various environments.

Q: How many wires do RTDs usually have, and what is the purpose of a three - wire or four - wire configuration?

A: RTDs can have two, three, or four wires. A two - wire RTD is the simplest configuration but is subject to lead wire resistance errors. A three - wire configuration is commonly used in industrial applications as it allows for the elimination of lead wire resistance errors by using the third wire to measure the voltage drop across the lead wires separately from the RTD element. A four - wire configuration provides even more accurate measurement by completely eliminating the effects of lead wire resistance, as it allows for the independent measurement of the current through the RTD and the voltage across it.

Q: What are the common causes of RTD failure?

A: Common causes of RTD failure include mechanical damage to the element or wiring, exposure to temperatures beyond the specified operating range, moisture ingress or contamination, vibration and shock, ageing and wear of the component, and poor installation practices such as incorrect wiring or insufficient protection from the environment.

Q: Can RTDs be used in hazardous environments?

A: Yes, RTDs can be used in hazardous environments. Specialized RTDs with explosion - proof or intrinsically safe designs are available for use in areas where there is a risk of explosion due to the presence of flammable gases, vapors, or dust. These RTDs are designed to prevent the ignition of the hazardous substances by ensuring that any electrical sparks or heat generated during operation are contained within a safe enclosure.

https://www.sic-components.com/rtd-resistance-temperature-detector

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)