- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Flexible Integrated Circuits

In the ever-evolving landscape of electronics, flexible integrated circuits (ICs) have emerged as a revolutionary technology, challenging the traditional norms of rigid electronics. This article will delve into the intricacies of flexible ICs, exploring their definition, working principles, types, characteristics, roles, applications, selection criteria, and the comparison with fixed ICs.

What is Flexible Integrated Circuits? https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

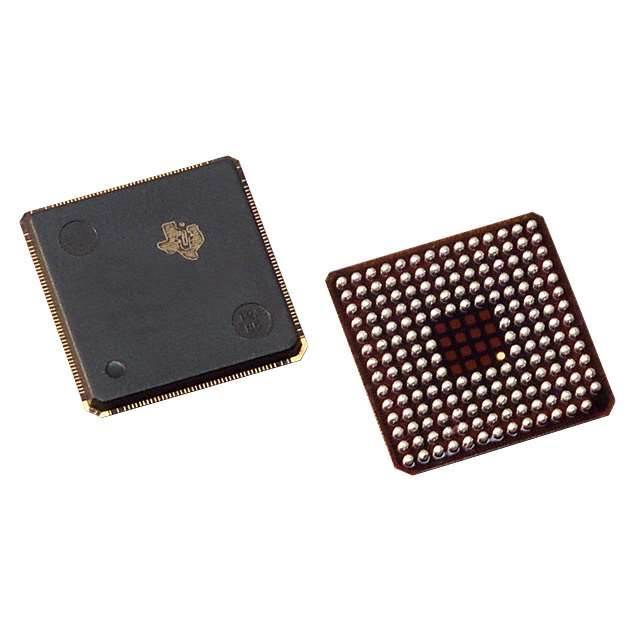

Flexible integrated circuits are a type of electronic circuit that combines the functionality of conventional rigid electronics with the flexibility of printed electronics. At their core, they aim to integrate various electronic components, such as integrated circuits, sensors, antennas, batteries, and photovoltaic cells, onto a flexible substrate. A prototypical flexible hybrid electronic (FHE) circuit, a common form of flexible ICs, typically includes an integrated circuit along with printed sensors, an antenna, a thin film battery, and even thin film photovoltaic elements. However, for a circuit to be classified as FHE, it must incorporate at least both printed and placed functionality, although not all components need to be printed or included.

The Working Principle Of Flexible Integrated Circuits https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

The fundamental principle of flexible ICs lies in the ability to mount an integrated circuit, which is usually manufactured separately using photolithography, onto a flexible substrate and connect it to printed interconnects. However, this process is not without challenges. Silicon dies, which are commonly used in traditional ICs, are rigid and have a significantly different form factor and thermal expansion coefficient compared to the flexible substrate. This mismatch can lead to mechanical stress and potential failure of the circuit during bending or flexing.

Another challenge is related to the semiconductors used. Alternative semiconductors to silicon, such as metal oxides and organic semiconductors, have much lower electron mobilities, making it difficult to achieve high-performance and high-yield manufacturing processes. To overcome these challenges, various techniques are employed. For instance, thinning existing silicon chips to a very thin layer, often just above the first junction, and encapsulating them in a protective layer like polyimide can make them more flexible. Additionally, new manufacturing processes are being developed to deposit and pattern materials on flexible substrates accurately.

Types and Characteristics of Flexible Integrated Circuits https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

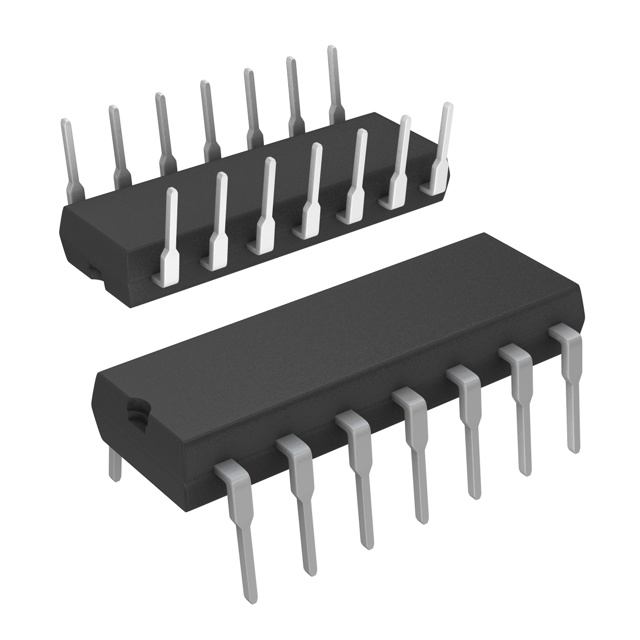

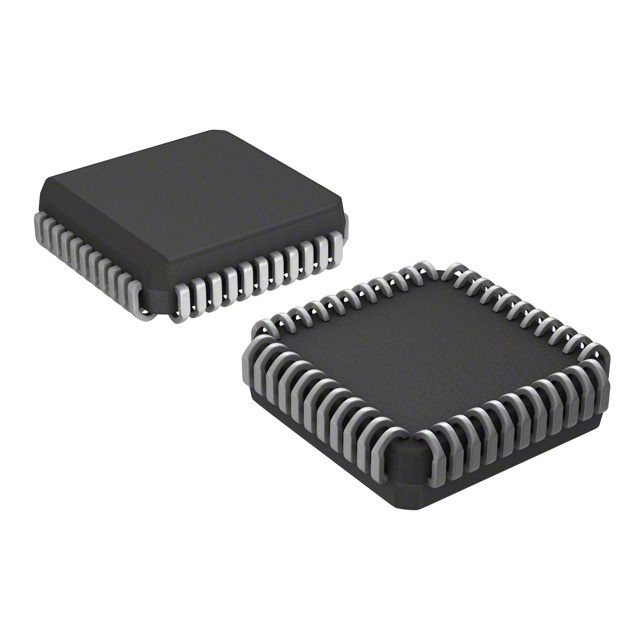

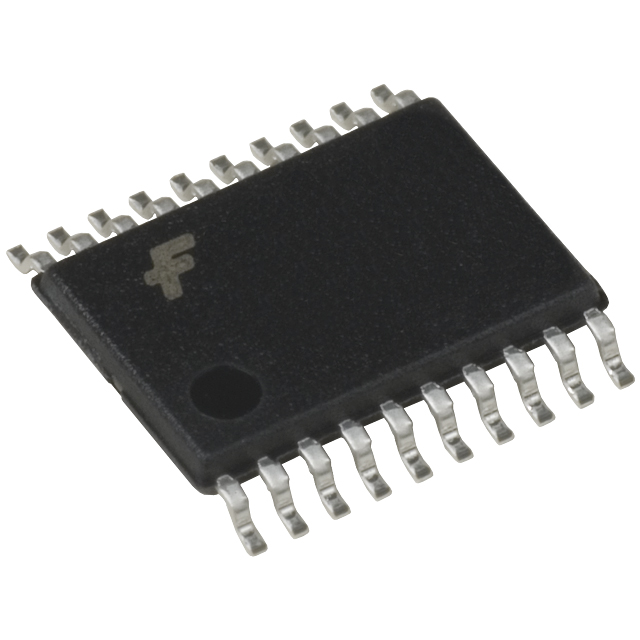

Packaged ICs: A Temporary Solution

One approach is to solder a conventional packaged rigid IC to a (usually stiffened) flexible substrate, resulting in what are commonly known as flexible printed circuits (FPCBs). While this method provides a relatively quick way to incorporate existing ICs into flexible applications, it has limitations. Mounting a packaged IC restricts the flexibility of the circuit and eliminates the possibility of roll-to-roll (R2R) manufacturing, a highly efficient mass-production technique for flexible electronics.

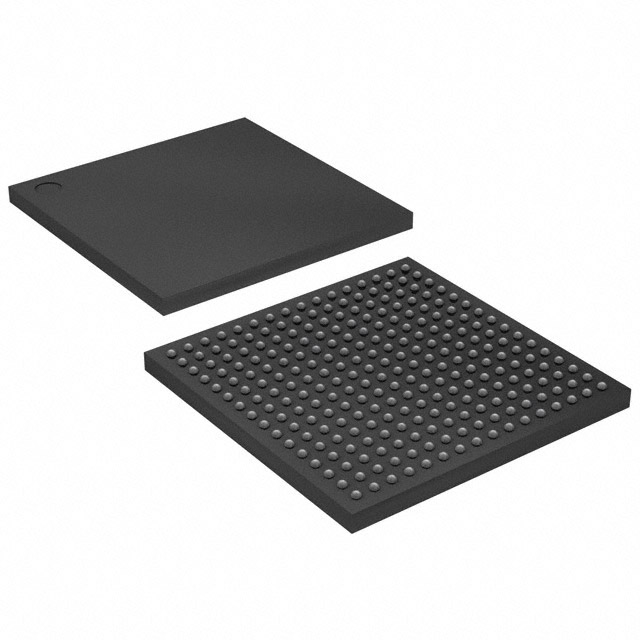

Flexible ICs From Thinned Si

Another type is created by thinning existing silicon chips. By grinding the silicon dies to a thickness as low as 10 micrometers and encapsulating them in polyimide, flexible ICs can be produced. These thinned silicon-based flexible ICs are already available in small volumes for prototyping. For example, there are modules with features like analog-to-digital converters and UHF RFID capabilities in a compact size. However, the current bottleneck in their flexibility lies in the attachment method, which is an area of active research and innovation.

Natively Flexible ICs From Metal Oxide

Natively flexible ICs, which are currently used for relatively simple applications such as RFID tags and sensor read-out, represent another important type. These ICs are fabricated by applying photolithographic techniques to deposit metal, insulator, and metal oxide films sequentially on a polyimide substrate. They offer the advantage of low production costs, with chips costing as little as $0.01 for applications with less than 100,000 logic gates. This cost-effectiveness makes them ideal for applications where cost is a critical factor, such as smart packaging.

The Role of Flexible Integrated Circuits

Flexible ICs play a crucial role in expanding the boundaries of electronic applications. They enable the development of electronics that can conform to various shapes and surfaces, which was previously not possible with rigid ICs. This flexibility opens up new opportunities in numerous fields, from wearable technology to healthcare, automotive, and smart packaging. In wearable devices, flexible ICs can be integrated into clothing or accessories, providing continuous health monitoring, communication, and entertainment functions without restricting the user's movement. In the automotive industry, they can be used for in-car sensors, displays, and antennas, enhancing the vehicle's functionality and aesthetics.

Applications of Flexible Integrated Circuits https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

Wearable Technology

In the realm of wearable technology, flexible ICs are a game-changer. They can be incorporated into smartwatches, fitness trackers, and even smart clothing. For example, smart clothing with integrated flexible sensors can monitor vital signs such as heart rate, body temperature, and movement, providing valuable health data in real-time. These devices can also be connected wirelessly to smartphones or other devices, enabling seamless data transfer and communication.

Healthcare

In healthcare, flexible ICs are used for various applications, including advanced wound care technologies, electronic skin patches, and remote patient monitoring. Electronic skin patches with integrated sensors can continuously monitor a patient's physiological parameters, such as blood pressure and glucose levels, without the need for invasive procedures. This data can be transmitted wirelessly to healthcare providers, allowing for timely and accurate medical interventions.

Automotive

In the automotive industry, flexible ICs are finding increasing applications. They can be used for in-car sensors to monitor tire pressure, engine performance, and vehicle dynamics. Flexible displays can also be integrated into the dashboard, providing a more immersive and customizable user experience. Additionally, flexible antennas can be embedded in the vehicle's body, improving the reception of wireless signals.

Smart Packaging

Smart packaging is another area where flexible ICs are making a significant impact. Natively flexible metal-oxide based ICs, with their low cost and simple functionality, are ideal for applications such as RFID tags in smart packaging. These tags can be used for inventory management, product authentication, and tracking the supply chain, ensuring the integrity and safety of products.

How to choose Flexible Integrated Circuits? https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

When choosing flexible integrated circuits, several factors need to be considered. Firstly, the application requirements play a crucial role. For applications with complex processing requirements, such as replacing conventional printed circuit boards, thinned silicon dies encapsulated in polyimide may be a suitable choice due to their relatively high performance. However, for cost-sensitive applications like smart packaging, natively flexible metal-oxide based ICs are more appropriate.

Secondly, the flexibility and bendability requirements of the application should be taken into account. Different types of flexible ICs have varying degrees of flexibility, and the chosen IC should be able to withstand the expected bending and flexing without compromising its performance or reliability. Additionally, the manufacturing process and cost of the IC are important considerations. Roll-to-roll manufacturing-compatible ICs are more suitable for mass production, while custom or low-volume production may require different manufacturing approaches.

Flexible ICs vs Fixed Ics https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

The most obvious difference between flexible ICs and fixed ICs is their physical form. Fixed ICs are rigid and are typically mounted on rigid printed circuit boards, which limits their application in scenarios where flexibility is required. In contrast, flexible ICs can conform to various shapes and surfaces, enabling new form factors and applications.

In terms of performance, traditional fixed ICs, especially those made of silicon, generally offer higher processing speeds and better electrical performance due to the well-established manufacturing processes and high electron mobilities of silicon. However, flexible ICs are constantly evolving, and their performance is improving. For some applications where high performance is not the primary requirement, such as simple sensing and communication in smart packaging, flexible ICs can provide sufficient functionality at a lower cost.

Cost is also a significant differentiator. The manufacturing process of fixed ICs, especially for high-performance chips, can be very expensive, involving complex photolithography and semiconductor fabrication steps. Flexible ICs, especially natively flexible ones made using simpler processes and materials, can be produced at a much lower cost, making them more accessible for a wide range of applications.

In conclusion, flexible integrated circuits represent a significant advancement in the field of electronics, offering new possibilities and applications that were previously unattainable with traditional rigid ICs. As the technology continues to evolve and mature, we can expect to see even more innovative uses of flexible ICs in various industries, transforming the way we interact with and use electronic devices.

https://www.sic-components.com/integrated-circuits-ics?manufacturer_id=563

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)