- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

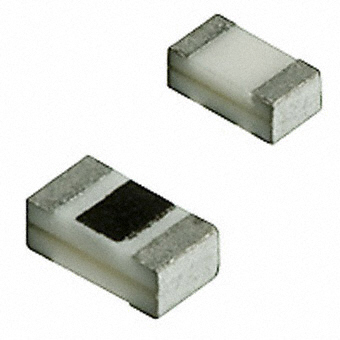

Capacitor Size Chart: The Ultimate Guide To Capacitor Sizes

Summary: This article provides an in-depth and comprehensive introduction to capacitors as electronic components, detailing the critical impact of their size on circuit and device performance. It covers not only the fundamental concepts, types, and size standards of capacitors but also offers a meticulous interpretation of their specific size requirements in various application scenarios, as well as compatibility considerations during replacement. The aim is to help readers thoroughly understand the significance of capacitor size selection and enable them to choose and use capacitors correctly and appropriately in practical applications.

As one of the three passive electronic components, a capacitor is an energy storage element composed of two conductive electrodes and an insulating medium between them. Its basic characteristics can be expressed by the formula:

C = ε·A/d

Where:

C: Capacitance (Farad, F)

ε: Dielectric constant

A: Plate area

d: Plate spacing

Analysis of Core Parameters

Parameter Definition Typical Unit Importance

Capacitance The ability to store charge μF/nF/pF Determines the amount of energy stored

Voltage Rating The maximum operating voltage V Ensures safe operation

Tolerance The range of capacitance deviation % Affects circuit accuracy

ESR (Equivalent Series Resistance) Equivalent series resistance Ω Crucial for high-frequency performance

Overview of Capacitor Types

Classification of Fixed Capacitors

Ceramic Capacitors:

Characteristics: Small size, good high-frequency characteristics

Capacitance range: 1pF~100μF

Typical packages: 0402/0603/0805, etc.

Electrolytic Capacitors:

Aluminum electrolytic: Large capacitance (1μF~10000μF)

Tantalum electrolytic: High stability (1μF~1000μF)

Applications: Power supply filtering, energy storage

Film Capacitors:

Types: Polyester film/Polypropylene film

Characteristics: Low loss, high precision

Suitable for: High-frequency circuits, filtering networks

Variable Capacitors

Adjustable range: 5~500pF

Application scenarios: RF tuning circuits

Ceramic Capacitors VS. Electrolytic Capacitors VS. Film Capacitors

Type Capacitance Range Voltage Range Temperature Characteristics Typical Applications

Ceramic 1pF-100μF 6.3V-10kV X7R/X5R stable High-frequency decoupling

Electrolytic 0.1μF-1F 6.3-500V Poor Power supply filtering

Film 1nF-100μF 50-2000V Excellent Precision analog circuits

Detailed Explanation of Size Specification

SMD Standard Size Comparison Table

Package Code Metric Size (mm) Imperial Size (inch) Typical Capacitance Range

01005 0.4×0.2 0.016×0.008 0.1pF~1nF

0402 1.0×0.5 0.016×0.008 0.1pF~10nF

0603 1.6×0.8 0.06×0.03 1pF~100nF

0805 2.0×1.25 0.08×0.05 10pF~1μF

Size Specifications of Electrolytic Capacitors

Diameter: 5mm~50mm

Height: 10mm~100mm

Capacitance-volume ratio: Approximately 100μF/cm³ (Aluminum electrolytic)

Professional Selection Methodology

1. Principle of Capacitance Calculation

For Power Supply Filtering Applications:

C ≥ (I·Δt)/ΔV

Where:

I: Load current

Δt: Discharge time

ΔV: Allowable ripple voltage

For Motor Starting Capacitors:

Empirical formula: C(μF) ≈ (1000·P)/(V²·2πf)

P: Power (W), V: Voltage (V), f: Frequency (Hz)

2. Principles for Voltage Rating Selection

Operating voltage ≤ 80% of the rated voltage

Transient voltage ≤ Rated voltage

Derating curve reference:

In an 85℃ environment: Derate by 20%

In a 105℃ environment: Derate by 40%

Industry Application Specifications

1. Capacitor Selection Table for HVAC Systems

Equipment Type Capacitance Range (μF) Voltage Level (V) Size Reference (mm)

1 HP air conditioner 20~30 370~440 Φ30×50

3 HP air conditioner 40~50 440~480 Φ35×60

5 HP air conditioner 60~80 480~550 Φ40×80

2. Specifications for Motor Starting Capacitors

Motor Power (HP) Starting Capacitor (μF) Running Capacitor (μF)

1/4 50~75 4~10

1/2 100~125 10~20

1 150~200 20~30

3. Switching Power Supply Design

Input Filtering: X2 safety capacitor (100nF - 1μF)

Output Filtering: Low ESR electrolytic capacitor (220 - 1000μF)

High-frequency Decoupling: Ceramic capacitor (0.1μF, 0805 package)

4. Internet of Things (IoT) Devices

RF Matching: 1 - 10pF NP0 ceramic capacitor

Power Management: 10μF 0603 MLCC (Multilayer Ceramic Capacitor)

RTC (Real-Time Clock) Backup: 0.1F supercapacitor

Key Points in Engineering Practice

1. Installation Precautions

Polarity Confirmation: The positive and negative poles of electrolytic capacitors must be strictly distinguished.

Spacing Maintenance: High-voltage capacitors need to ensure sufficient creepage distance.

Thermal Management:

Keep away from heat sources.

Install heat sinks for high-current applications.

Mechanical Fixation: Special brackets are required for large capacitors.

2. Analysis of Failure Modes

Capacitance Decay: Caused by the drying up of the electrolyte (approximately 5~10% per year)

Increase in ESR: Caused by the aging of the dielectric

Short-circuit Failure: Caused by dielectric breakdown

Open-circuit Fault: Caused by the breakage of the lead wire

Development of Cutting-edge Technologies

1. New Capacitor Technologies

Supercapacitors:

Capacitance: 0.1~3000F

Characteristics: High power density (10kW/kg)

Applications: New energy storage, instantaneous large current power supply

Progress in MLCC Technology:

Ultra-thin dielectric: <1μm

High capacitance and miniaturization: 100μF/0805 package

Solid Electrolytic Capacitors:

Service life: >50,000 hours

ESR: Reduced by more than 50%

Frequently Asked Questions

Q: Can a capacitor with a larger capacitance be used to replace the original specification?

A: Comprehensive considerations are required:

The voltage rating must be ≥ the original specification.

The physical size needs to be suitable for the installation space.

In high-frequency applications, pay attention to the change in ESR.

For power supply filtering, it can be appropriately increased (+20%).

Q: Can capacitors of different materials be used interchangeably?

A: Principles:

For high-frequency decoupling: Ceramic capacitors are preferred.

For large-capacity energy storage: Electrolytic capacitors are necessary.

In key timing circuits: Avoid mixing capacitors with different temperature characteristics.

Q: How to determine if a capacitor is aging?

A: Detection methods:

Capacitance test: Replace if it deviates from the nominal value by >20%.

ESR measurement: Replace if it exceeds twice the initial value.

Appearance inspection: Replace immediately if there is bulging or leakage.

This technical guide comprehensively covers all key aspects of capacitors, from basic theories to engineering practices, providing a complete selection and application reference system for electronic engineers. In actual design, it is recommended to combine specific application scenarios, refer to the latest specification sheets provided by manufacturers, and fully consider the impact of environmental factors on the performance of capacitors to achieve the optimal circuit design.

Welcome to our collection of common capacitor sizes! Whether you are a hobbyist, technician, or engineer, you will find the perfect capacitor for your electronic projects and devices. Our range includes the most widely used capacitance values, ensuring that you have the right component for your application. From tiny ceramic capacitors suitable for compact circuit designs to larger electrolytic capacitors for power supply and filtering applications, we have a variety of sizes to accommodate various needs. Each capacitor is designed to provide reliable and stable performance, meeting industry standards for quality and efficiency. Our common capacitor sizes are suitable for a wide range of electronic equipment, including audio amplifiers, power supplies, LED lighting, motor control systems, and more. With our comprehensive selection, you can easily find the right capacitor for your specific requirements, making your projects easier and more efficient. Discover the perfect common capacitor sizes for your electronic needs today!

https://www.sic-components.com/capacitors

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)