The BTS7960 is a high - current half - bridge motor driver IC. It integrates a p - channel high - side MOSFET, an n - channel low - side MOSFET, and a driver IC in one package. With features like logic - level inputs, adjustable slew rate, and comprehensive protection against over - temperature, over - voltage, and short - circuits, it ensures reliable operation. Capable of handling significant currents, it's widely used in robotics, industrial automation, and motor control for household appliances and electric vehicles. In this article, we’ll cover the key specifications, pin configurations, and benefits of using the BTS7960B, as well as some practical tips for optimizing its performance in various use cases.

1. Features and Characteristics of BTS7960B

1.1 Key Features

High - Current Handling: As a fully integrated high - current half - bridge motor driver IC, the BTS7960B can handle substantial currents, with a typical path resistance of 16 mΩ at 25 °C. This low resistance allows for efficient power transfer and minimizes power losses during operation, making it suitable for driving high - power motors.

PWM Capability: It supports pulse - width modulation (PWM) up to 25 kHz, combined with active freewheeling. This high - frequency PWM control enables precise adjustment of motor speed, providing smooth and accurate control over motor operations. The active freewheeling feature helps in reducing voltage spikes and protecting the circuit during the motor's transition phases.

Comprehensive Protection Mechanisms: The BTS7960B is equipped with an array of protective features. It has over - temperature shut - down with latch behavior, which immediately halts operation when the temperature exceeds a safe threshold to prevent damage from overheating. Overvoltage lockout and undervoltage shut - down safeguard the chip from abnormal voltage conditions. Additionally, it offers switched - mode current limitation, reducing power dissipation in case of overcurrent, with a current limitation level of 43 A typical, and short - circuit protection to ensure the integrity of the circuit and the connected motor.

Logic - Level Inputs: The driver circuit features logic - level inputs, which simplifies the interface with microcontrollers and other digital logic circuits. This compatibility allows for easy integration into a wide range of control systems, making it accessible for both novice and experienced engineers.

Diagnosis and Slew Rate Adjustment: With status flag diagnosis and current - sense capability, the BTS7960B enables real - time monitoring of the motor's operating conditions. Engineers can detect potential issues early and take corrective actions. The adjustable slew rates for the power switches help in optimizing electromagnetic interference (EMI) performance, reducing unwanted noise in the system.

1.2 Technical Characteristics

Power Supply and Voltage Range: It operates within a voltage range of 5.5V to 27.5V for both the supply and load. This wide voltage range makes it adaptable to different power sources and application requirements, from battery - powered devices to industrial power supplies.

Temperature Range: The BTS7960B can function reliably in a temperature range from - 40°C to 150°C, allowing it to be used in diverse environmental conditions, including harsh industrial settings and outdoor applications.

Current Specifications: It has a maximum output current of 60A, with an output current per channel of 40A. The quiescent current is a low 7μA at 25 °C, contributing to energy efficiency when the motor is not actively running.

2. Symbol, Footprint, and Pin Configuration of BTS7960B

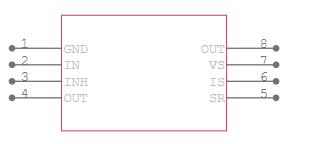

2.1 BTS7960B Symbol

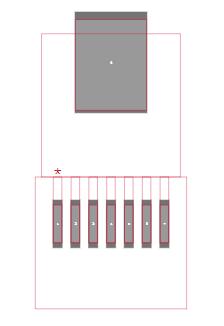

2.2 BTS7960B Footprint

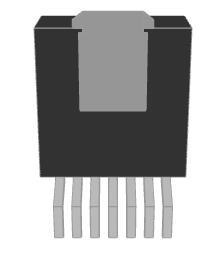

2.3 BTS7960B 3D Model

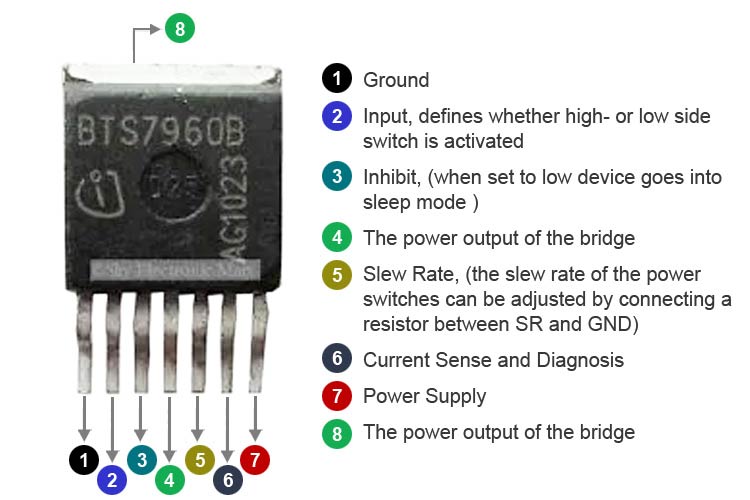

2.4 BTS7960B Pin Configuration

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | GND | This pin is the ground connection, providing a common reference point for the electrical circuit. A stable ground connection is essential for the proper operation of the chip and helps in preventing voltage fluctuations. |

| 2 | IN | The input pin defines whether the high - or low - side switch is activated. It receives control signals from a microcontroller or other logic circuits, determining the direction and operation of the motor. |

| 3 | INH | When set to low, this inhibit pin puts the device into sleep mode, reducing power consumption significantly. This feature is especially useful in battery - powered applications where energy conservation is a priority. |

| 4, 8 | OUT | These pins are the power output channels of the bridge. They are connected to the motor and supply the necessary current to drive it. The current flowing through these pins determines the torque and speed of the motor. |

| 5 | SR | The slew rate pin allows for the adjustment of the slew rate of the power switches. By connecting a resistor between SR and GND, engineers can control the rate at which the voltage across the switches changes, minimizing EMI and achieving smoother transitions. |

| 6 | IS | This pin is dedicated to current sensing and diagnosis. It provides valuable information about the current flowing through the motor, enabling real - time monitoring and protection against overcurrent conditions. |

| 7 | VS | The power supply pin supplies the necessary voltage to power the module. A stable and appropriate voltage input is crucial for the reliable operation of the BTS7960B and the connected motor. |

4. BTS7960B Layout Considerations

Stray Inductance Minimization: High currents in the BTS7960B have fast switching times, and minimizing stray inductance in the power bridge design is essential. Stray inductance can cause voltage spikes and ringing, which may damage the chip and other components. To reduce stray inductance, short and wide traces should be used for power connections, and the layout should be kept as compact as possible.

Grounding: As the BTS7960B does not have separate power ground and logic ground pins, it is crucial to minimize the offset between the ground connection of components such as the slew rate resistor, current sense resistor, and the GND pin. In multi - chip configurations like H - bridges or B6 - bridges, keeping the voltage offset between the GND pins of different devices to a minimum helps in maintaining stable operation and reducing noise.

Capacitor Placement: Using ceramic capacitors from VS to GND near each device provides a low - inductance path for current to the switching stage. A capacitor value of around 470 nF is typically suitable. These capacitors help in reducing noise and ground bounce, ensuring a stable power supply to the chip.

Input Protection: The digital inputs of the BTS7960B need to be protected against excessive currents caused by induced voltage spikes. Series resistors in the range of 10 kΩ can be used to limit the current and safeguard the input pins from damage.

5. Where and How to use BTS7960B?

5.1 Where to Use BTS7960B?

Robotics: In robotic systems, it is used for precise motion control of motors. Whether it's a small hobby robot or a complex industrial robot, the BTS7960B enables accurate control of motor speed and direction, allowing the robot to perform tasks with precision.

Household Appliances: For motor drives in household appliances such as washing machines and air conditioners, the BTS7960B provides reliable and efficient motor control. It can handle the varying loads and operating conditions of these appliances, ensuring smooth operation and energy efficiency.

Industrial Automation: In industrial automation systems, the BTS7960B is employed in motor control systems for conveyor belts, robotic arms, and other machinery. Its high - current handling capability and protective features make it suitable for the demanding environment of industrial applications.

Electric Vehicles: In electric vehicles like e - bikes and scooters, the BTS7960B controls the motor, enabling efficient power transfer and smooth acceleration. It helps in optimizing the vehicle's performance and extending the battery life.

5.2 How to Use BTS7960B?

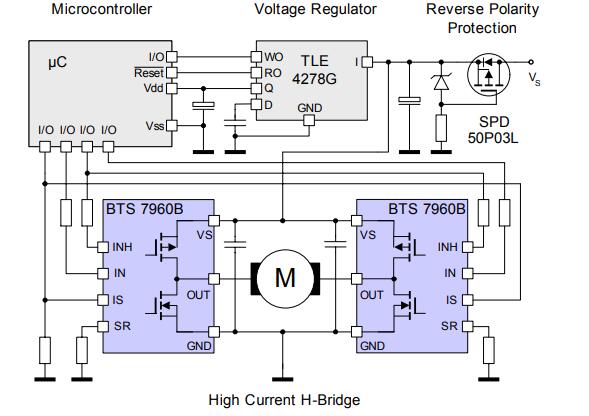

Circuit Connection: To use the BTS7960B, it needs to be connected to a power source, a microcontroller or other control circuit, and the motor. The power supply pins (VS and GND) are connected to the appropriate voltage source, and the control pins (IN, INH) are connected to the output pins of the microcontroller. The output pins (OUT) are then connected to the motor.

PWM Control: A microcontroller is typically used to generate PWM signals and send them to the IN pin of the BTS7960B. By adjusting the duty cycle of the PWM signal, the speed of the motor can be controlled. The direction of the motor can be changed by reversing the logic levels on the control pins.

Initialization and Configuration: Before operation, the BTS7960B may need to be initialized. This may involve setting the appropriate slew rate by configuring the SR pin resistor, enabling or disabling certain protection features if possible, and ensuring that the input signals are within the specified voltage range.

6. Applications of BTS7960B

6.1 Robot Motion Control

6.2 Motor Drives for Household Appliances

6.3 Motor Control Systems in Industrial Automation

6.4 Motor Control for Electric Vehicles

7. Pros and Cons of BTS7960B

7.1 Advantages

Comprehensive Protection: The BTS7960B's extensive protection features, including over - temperature, overvoltage, undervoltage, overcurrent, and short - circuit protection, make it highly reliable. These safeguards protect the chip, the motor, and the entire circuit from damage, reducing the risk of system failures and costly repairs.

Ease of Use: With its logic - level inputs and simple interface, the BTS7960B is easy to integrate into different control systems. It requires only a few peripheral components, which simplifies the circuit design process and reduces the overall complexity of the system.

High Efficiency: The low on - resistance and efficient power transfer of the BTS7960B contribute to high - efficiency motor driving. This results in reduced power consumption, which is beneficial for both battery - powered devices and energy - conscious applications.

High Integration: By integrating multiple functions such as motor drive, protection, and control into a single chip, the BTS7960B simplifies the overall system design. This high level of integration also improves the reliability of the system by reducing the number of interconnections and potential failure points.

7.2 Disadvantages

Higher Cost: Compared to some other motor driver components, the BTS7960B has a relatively higher cost. This can be a significant factor in projects with tight budgets, potentially limiting its use in cost - sensitive applications.

Complex Design Requirements: Designing a motor system with the BTS7960B requires careful consideration of various factors such as current and voltage limits, resistor and capacitor values, and PCB layout. Ensuring proper design to meet all the requirements can be challenging, especially for engineers with limited experience, and may require additional time and effort for testing and optimization.

8. How to Optimize the BTS7960B Chip?

8.1 Reasonable Motor Selection

8.2 Enhanced Heat Dissipation Design

8.3 Optimized Drive Circuit

8.4 Appropriate PWM Control

8.5 Optimal Resistor Selection

9. Different Packaging Options for BTS7960B

TO - 263 - 7 Package: This package is commonly used in high - power applications where efficient heat dissipation is required. Its design allows for better heat transfer to a heat sink, making it suitable for applications where the chip is expected to handle high currents and generate significant heat. The pin layout of the TO - 263 - 7 package is optimized for easy soldering and connection to the PCB.

TO - 252 - 15 Package: The TO - 252 - 15 package is more suitable for general - purpose power applications where intensive cooling is not a primary concern. It has a smaller form factor, which can be beneficial in space - constrained designs. The package provides multiple pins for power, control, and grounding, ensuring reliable electrical connections in a wide range of applications.

10.BTS7960B's Category-Motor Driver

Motor drivers are essential components in modern electronics, acting as the bridge between control signals and electric motors. Their primary function is to convert low-power control signals from microcontrollers or other sources into high-current signals capable of driving motors. This enables precise control over motor speed, direction, and torque, making them indispensable in a wide range of applications.

In robotics, motor drivers allow robots to move with accuracy, performing complex tasks with ease. In industrial automation, they ensure the smooth operation of machinery, optimizing productivity. Home appliances like washing machines and fans also rely on motor drivers for efficient functioning.

Advanced motor drivers come with features such as pulse-width modulation (PWM) for speed control, built-in protection against overcurrent, overvoltage, and overheating, and compatibility with different motor types, including DC motors, stepper motors, and brushless DC motors.

Among the notable motor drivers is the BTS7960B. Manufactured by Infineon (formerly related to Siemens Semiconductors), the BTS7960B stands out with its high-current handling ability, integrated protection mechanisms, and ease of use. Its combination of a p-channel high-side MOSFET, an n-channel low-side MOSFET, and a driver IC in one package makes it a reliable choice for applications where robust and efficient motor control is required, from robotics projects to industrial motor drives.

11.BTS7960B Manufacturer-Siemens Semiconductors

Siemens Semiconductors has made remarkable achievements in the Motor Driver field. In 2020, Siemens released a GaN-based drive as part of its Simatic Micro-Drive product line. By using gallium nitride (GaN) power transistors, this drive increased efficiency and achieved a faster motor response time. The mini drive, only two centimeters wide, requires no additional cooling due to GaN's properties. Siemens also introduced the fully electronic e-starter, Simatic ET 200sp e-starter, which uses semiconductor technology with silicon carbide MOSFETs. It offers short-circuit protection 1000 times faster and is virtually wear-free compared to traditional solutions. This ensures optimal protection for motors. It also neutralizes inrush currents, reducing starting currents and mechanical wear. Moreover, Siemens' products like the Simatic Micro-Drive safety and extra-low voltage family, with integrated GaN power transistors, cover a wide range of applications such as conveyor systems, stacker cranes, and AGVs. These achievements showcase Siemens Semiconductors' innovation and leadership in enhancing motor driver performance, efficiency, and reliability for diverse industrial needs.

Hot-selling products of SIC

71421LA55J8 UPD44165184BF5-E40-EQ3-A SST39VF800A-70-4C-B3KE IS66WV1M16DBLL-55BLI-TR AS4C32M16SB-7BIN W25Q16FWSNIG

AS7C34098A-20JIN 752369-581-C W957D6HBCX7I TR IS61LPS12836EC-200B3LI MX25L12875FMI-10G QG82915PL

Product information is from SIC Electronics Limited. If you are interested in the product or need product parameters, you can contact us online at any time or send us an email: sales@sic-chip.com.

Wishlist (0 Items)

Wishlist (0 Items)